XYZ Utilities O&M Manual Rev. 2.0 - November 1, 2019

The links below take you to subsections within the current topic.

8.0 PERSONAL PROTECTIVE EQUIPMENT (PPE)

9.0 DOCUMENTATION/RECORDKEEPING

The purpose of this section is to describe the procedures for distribution leakage surveys.

Text in maroon indicates a glossary term. Click the term to see the definition; click again to hide it.

This sections covers the following:

a. Summary of leak survey requirements for distribution facilities

b. Types of surveys conducted on pipeline facilities.

c. Procedures for conducting gas leak surveys.

Building - is any structure which is normally or occasionally entered by humans for business, residential or other purposes and in which gas could accumulate.

Buildings of Public Assembly (BPA) - Buildings of public assembly are defined as: buildings used for public assembly, including schools, churches, hospitals, theaters, municipal buildings and downtown areas.

Combustible Gas Indicator (CGI) – An instrument used to measure the levels of combustible gases and vapors present in air.

Confined Space – see Safety Manual 4.3

Gas – Means natural gas, flammable gas, or gas which is toxic or corrosive.

Hazardous Aboveground Leak – A Hazardous Aboveground Leak is one that: can be seen, heard, or felt (e.g., causes the blowing-off of leak detection soap), and requires immediate make-safe action (e.g., evacuation, shutoff, repair, etc.) because it is in a location that may endanger the public or property, or on inside piping, generates a minimum reading of 20% LEL or more in the general atmosphere of the structure.

Main – Means a distribution line that serves as a common source of supply for more than one service line.

Manhole or Vault - a subsurface structure that a person can enter.

Mobile Flame Ionization Unit (FIU)– An instrument that measures the concentration of hydrocarbons to enable the detection of gas leaks.

Pipeline – Means all parts of those physical facilities through which gas moves in transportation, including pipe, valves, and other appurtenances attached to pipe, compressor units, metering stations, regulator stations, holders, and fabricated assemblies.

Service Line – Means a distribution line that transports gas from a common source of supply to an individual customer, to two adjacent or adjoining residential or small commercial customers, or to multiple residential or small commercial customers served through a meter header or manifold.

Sustained Reading – a reading obtained with a continuous sampling, after adequate natural ventilation of a sufficient number of bar holes.

Tunnel - a subsurface passageway of a size large enough for a person to enter.

Yard line - means an underground fuel line that transports gas from the service line to the customer's building. If multiple buildings are being served, building shall mean the building nearest to the connection to the service line. For purposes of this definition, if aboveground fuel line piping at the meter location is located within five feet (5') of a building being served by that meter, it shall be considered to the customer's building and no yard line exists. At meter locations where aboveground fuel line piping is located greater than five feet (5') from the building(s) being served, the underground fuel line from the meter to the entrance into the nearest building served by that meter shall be considered the yard line and any other lines are not considered yard lines.

The link below takes you to the applicable federal regulation. The regulations will open in a new browser tab.

49 CFR 192.723

Field Operations/Construct and Maintain or designee shall be responsible to:

Serve as lead organization for this procedure.

Utilize trained personnel in the performance of leakage surveys.

Maintain a record of transmission pipelines, distribution mains and service lines to be leak surveyed.

Schedule transmission pipeline and distribution leakage surveys for each location based on appropriate criteria.

Provide maps, books, or other documentation of the facilities to be leak surveyed.

Verify the completion of all leakage surveys in a timely manner

Ensure the completion of all associated paperwork (i.e., maps, drawings, logs, books and forms)

Review and update all maps, drawings, books and forms with the most recent revisions

Monitor progress and completion of follow-up items

Review and maintain records of completed leakage surveys.

6.2 Distribution Survey Frequency

6.5 Leak Classification and Action Criteria

ViaData Pipeline Services has the capability of conducting mobile or walking leakage surveys using flame ionization detectors. Most surveys of mains and service lines are conducted by walking crews; however, if service lines and mains are accessible to vehicles, the mobile equipment may be used.

6.2 Distribution Survey Frequency

The Distribution Pipeline Leak Survey consists of a residential area gas leak survey, inter-city pipeline gas leak survey, and a business district gas leak survey. This survey shall be directed by the Field Operations Supervisor and completed within the following time frame:

| Residential Area | Once every 5 calendar years at intervals not exceeding 60 months

for cathodically protected steel or plastic mains and services

Once every 3 calendar years at intervals not exceeding 36 months for unprotected steel mains and services or cast iron mains |

| Inter-city Pipeline | Once every 5 calendar years at intervals not exceeding 60 months

Once every 3 calendar years at intervals not exceeding 36 months for unprotected steel main |

| Business District | Once each calendar year at intervals not exceeding 15 months |

Consideration shall also be given to increased frequency based on particular circumstances and conditions.

The gas leakage survey shall include all distribution facilities in the gas service area and all services from the main to the meter. Surveys are made with mobile or remote methane leak detector (See the video in Section 11.0 below for operating instructions) as the conditions permit. In addition, a gas detector survey must be conducted in business districts, including tests of the atmosphere in gas, electric, telephone, sewer, and water systems manholes, at cracks in pavement, and at other locations providing an opportunity for finding gas leaks.

While surveying, if a read occurs on the flame ionization unit, it shall be immediately rechecked and validated. If the leak is valid, it shall be pinpointed by means of bar test holes. Reads shall be taken with the CGI to determine the extent and classification of the leak. The area of migration shall also be determined. A leak report shall be prepared at this time for any leak found. This report also alerts the Construction and Maintenance and initiates repair of the leak. Priority for repair depends upon the leak classification. Any Grade 1 leak shall be given immediate attention. Other leaks shall be handled in a routine manner. Refer to Section 6.5 below for Leak Classification and Action Criteria.

All leak orders with the exception of swing joints, risers, and services that are pump tested shall be rechecked as necessary by the crew making the repair. If there is an indication of continued leakage, this procedure shall be repeated until the area is clear.

After the leak has been cleared, the leak order shall then be returned to Field Operations. Swing joints and riser leaks which are soap tested and services that are pump tested from main to meter shall be considered as being repaired without requiring a recheck. Orders for these type leaks shall be returned to the Field Operations at the time of the initial repair.

Consideration should be given to increased frequency for leakage survey based on the particular circumstances and conditions. Surveys should be conducted most frequently in those areas with the greatest potential for leakage and where leakage could be expected to create a hazard. Special one-time surveys should be considered following exposure of the pipeline to unusual stresses (such as shifting soils or blasting).

Factors to be considered in establishing the frequency of leakage surveys include the following:

1. Piping System: Age of pipe materials, type of facilities, operating pressure, leak history and other studies

2. Corrosion: Known areas of significant corrosion or areas where corrosive environments are known to exist

3. Piping Location: Proximity to buildings or other structures and the type and use of the buildings. Proximity to areas of concentrations of people

4. Environmental Conditions and Construction Activity: Conditions which would increase the potential for leakage and/or which would cause the leaking gas to migrate to an area where it could create a hazard (such as weather conditions, wall-to-wall pavement, porous soil conditions, areas of high construction activity, blasting, large earth moving equipment, heavy traffic, unstable soil, or areas subject to earth movement)

5. Other: Any other condition known to the operator which has significant potential to instigate a leak or to permit leaking gas to migrate to an area where it could result in a hazardous condition (such as an earthquake, subsidence, flooding, or an increase in operating pressure)

Business districts are the principal business areas in an urban community. In determining business districts, the following areas should be considered:

1. The general public regularly congregates for economic, industrial, religious, educational, health or recreational purposes

2. The majority of the buildings on either side of the street are utilized for commercial, industrial, religious, educational, health or recreational purposes

3. Gas facilities are under continuous paving that extends from the centerline of the thoroughfare to the building wall or from the main to the building wall

4. Any other location or site, which in the judgment of the operator should be so designated

Samples of each report are included. The original of all reports is to be maintained for the life of the facility.

6.5 Leak Classification and Action Criteria

The procedure established by ViaData Pipeline Services for handling gas leak complaint reports received from customers, the general public, ViaData Pipeline Services employees, or anyone else is outlined in the company's Emergency Plan. The following establishes a procedure by which leakage indications of flammable gas can be graded and controlled. Particular care must be taken to determine whether or not any leakage discovered is entering a building or sewer system.

(1) When evaluating any suspected gas leak, the initial step is to determine the perimeter of the potential leak area. When the perimeter extends to a building wall, the investigation should continue into the building.

(2) Leaks shall be isolated to the general location of mains and services; meter set assemblies, district regulators, customer's piping or appliances.

(3) Appropriate personnel shall then classify the leak and take action in accordance with the following schedule.

Grade 1 Leak Definition

A Grade 1 leak is one that represents an existing or probable hazard to persons or property, and requires immediate repair or continuous action until the conditions are no longer hazardous.

Grade 1 Leak - Examples

1. Any leak which, in the judgment of operating personnel at the scene, is regarded as an immediate hazard

2. Escaping gas that has ignited

3. Any indication of gas which has migrated into or under a building, or into a tunnel

4. Any reading at the outside wall of a building, or where gas would likely migrate to an outside wall of a building

5. Any reading of 80% LEL, or greater, in a confined space

6. Any reading of 80% LEL, or greater, in small substructures (other than gas associated substructures) from which gas would likely migrate to the outside wall of a building

7. Any leak that can be seen, heard, or felt, and which is in a location that may endanger the general public or property

Grade 1 Leak - Action Criteria

The Grade 1 leak requires prompt action to protect life and property, and continuous action until the conditions are no longer hazardous. The prompt action in some instances may require one or more of the following:

1. Implementation of the Emergency Plan

2. Evacuation of premises

3. Blocking off an area

4. Rerouting traffic

5. Elimination of ignition sources

6. Stopping the flow of gas by closing valves, etc.

7. Notification of police and fire departments

Grade 2 Leak - Definition

A Grade 2 leak is one that is recognized as being non-hazardous at the time of detection but justifies scheduled repair based on probable future hazard.

Grade 2 Leak - Examples

1. Leaks Requiring Action Ahead of Ground Freezing or Other Adverse Changes in Venting Conditions.

Any leak which, under frozen or other adverse soil conditions, would likely migrate to the outside wall of a building.

2. Leaks Requiring Action within Six Months.

a. Any reading of 40% LEL, or greater under a sidewalk in a wall-to-wall paved area that does not qualify as a Grade 1 Leak.

b. Any reading of 100% LEL, or greater, under a street in a wall-to-wall paved area that has significant gas migration and does not qualify as a Grade 1 Leak.

c. Any reading less than 80% LEL in small substructures (other than gas associated substructures) from which gas would likely migrate creating a probable future hazard.

d. Any reading between 20% LEL and 80% LEL in a confined space.

e. Any reading on a pipeline operating at 30% SMYS or greater, in a Class 3 or 4 location, which does not qualify as a Grade 1 leak.

f. Any reading of 80% LEL, or greater, in gas associated substructures.

g. Any leak which, in the judgment of operating personnel at the scene, is of sufficient magnitude to justify scheduled repair.

Grade 2 - Action Criteria

Leaks should be repaired or cleared within one calendar year, but no later than 15 months from the date the leak was reported. In determining the repair priority, criteria such as the following should be considered:

1. Amount and migration of gas

2. Proximity of gas to buildings and subsurface structures

3. Extent of pavement

4. Soil type, and soil conditions (such as frost cap, moisture and natural venting)

Grade 2 leaks should be reevaluated at least once every 6 months until cleared. The location and magnitude of the leakage condition should determine the frequency of reevaluation.

Grade 2 leaks may vary greatly in degree of potential hazard. Some Grade 2 leaks, when evaluated by the above criteria, may justify scheduled repair within the next five working days. Others will justify repair within 30 days or during the working day on which the leak is discovered. These situations should be brought to the attention of the individual responsible for scheduling leak repair.

On the other hand, many Grade 2 leaks, because of their location and magnitude, can be scheduled for repair on a normal routine basis with periodic re-inspection as necessary.

Grade 3 Leak - Definition

A Grade 3 leak is one that is non-hazardous at the time of detection and can be reasonably expected to remain non-hazardous.

Grade 3 Leak - Examples

Leaks Requiring Reevaluation at Periodic Intervals.

1. Any reading of less than 80% LEL in small gas associated substructures

2. Any reading under a street in areas without wall-to-wall paving where it is unlikely the gas could migrate to the outside wall of a building

3. Any reading of less than 20% LEL in a confined space.

Grade 3 Leak - Action Criteria

These leaks shall be reevaluated during the next scheduled survey, or within 15 months of the date reported, whichever occurs first, until the leak is re-graded or no longer results in a reading.

The adequacy of leak repairs should be checked before back filling by soap testing and using leak detection equipment. The perimeter of the leak area should be checked with a CGI. Where there is residual gas in the ground after the repair of a Grade 1 leak, a follow-up inspection should be made as soon as practical after allowing the soil atmosphere to vent and stabilize, but in no case later than one month following the repair. In the case of other leak repairs, the need for a follow-up inspection should be determined by the [Title of Person Responsible]. Leaks not repaired should be reevaluated as listed in the action criteria.

The shaded sections below show state-specific information that can be shown or hidden using the Filter feature.

The links below take you to locations within a different topic. (If you are using a filter there may be no active links shown below.)

State Specific: Massachusetts OQ Tasks:

Task #6 – Inspecting for atmospheric corrosion

Task #8 – Visually inspecting for internal corrosion

Task #18 – Conducting gas leakage surveys

Task #19 – Patrolling and inspecting pipelines

Task #20 – Investigating leak/odor complaints

Task #70 – Properties of natural gas and abnormal operating conditions

State Specific: New Hampshire OQ Tasks:

Task #6 – Inspecting for atmospheric corrosion

Task #8 – Visually inspecting for internal corrosion

Task #18 – Conducting gas leakage surveys

Task #19 – Patrolling and inspecting pipelines

Task #20 – Investigating leak/odor complaints

Task #70 – Properties of natural gas and abnormal operating conditions

Task #70P - Properties of Propane Air/abnormal operating conditions

State Specific: Georgia OQ Tasks:

Task #I-9 – Internal Corrosion Control

Task #I-10 – Atmospheric Corrosion

Task #M-1 – Surveying Leaks

Task #M-3 – Locating and Marking Lines

Task #M-8 – Preventing accidental ignition

Task #M-13 – Emergency Response

Task #M-15 – Leak Classification

Task #M-16 – Recognize and react to abnormal operating conditions

Task #M-17 – Installing/Maintaining Pipeline Markers

State Specific: Iowa OQ Tasks:

Task #I-9 – Internal Corrosion Control

Task #I-10 – Atmospheric Corrosion

Task #M-1 – Surveying Leaks

Task #M-3 – Locating and Marking Lines

Task #M-8 – Preventing accidental ignition

Task #M-13 – Emergency Response

Task #M-15 – Leak Classification

Task #M-16 – Recognize and react to abnormal operating conditions

Task #M-17 – Installing/Maintaining Pipeline Markers

8.0 PERSONAL PROTECTIVE EQUIPMENT (PPE)

Observe all personnel and procedural safety procedures as necessary per job requirements.

9.0 DOCUMENTATION/RECORDKEEPING

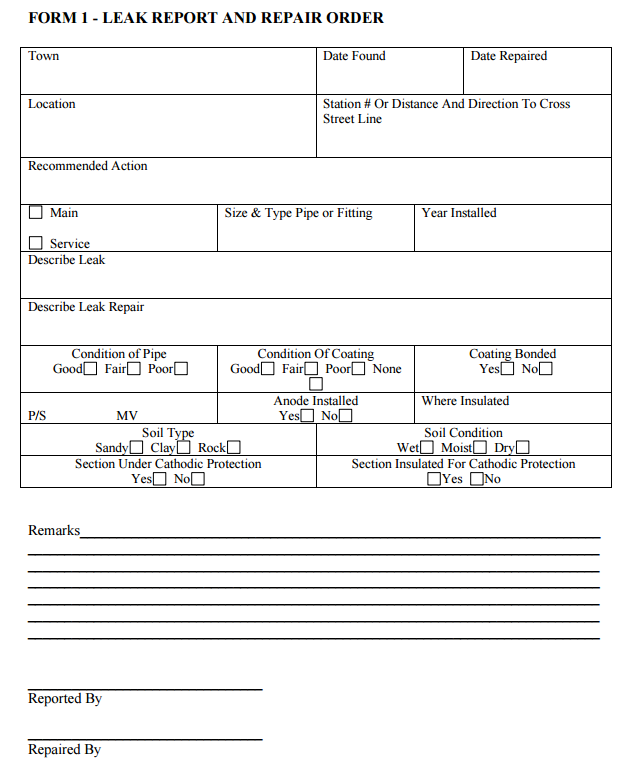

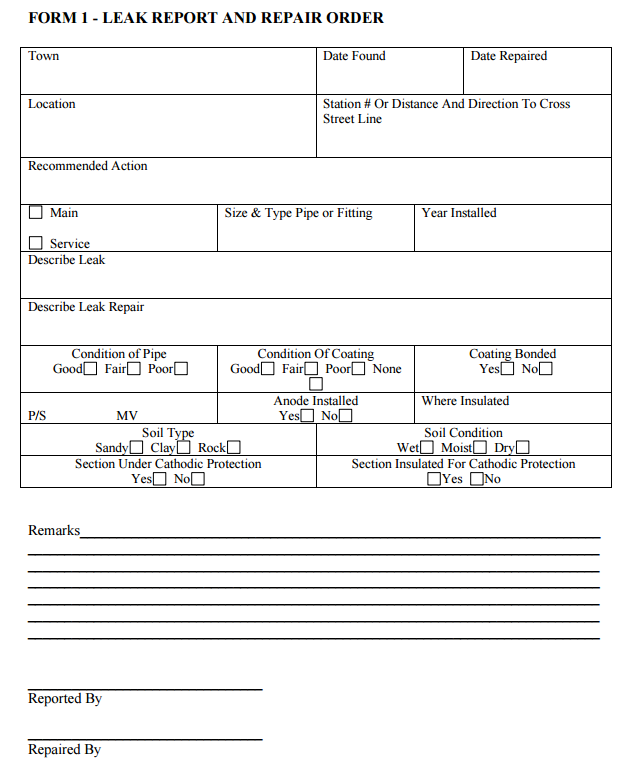

1. Leak Report and Repair Order must be completed by the Senior Leak Survey Technician to document the location and grade of the leak.

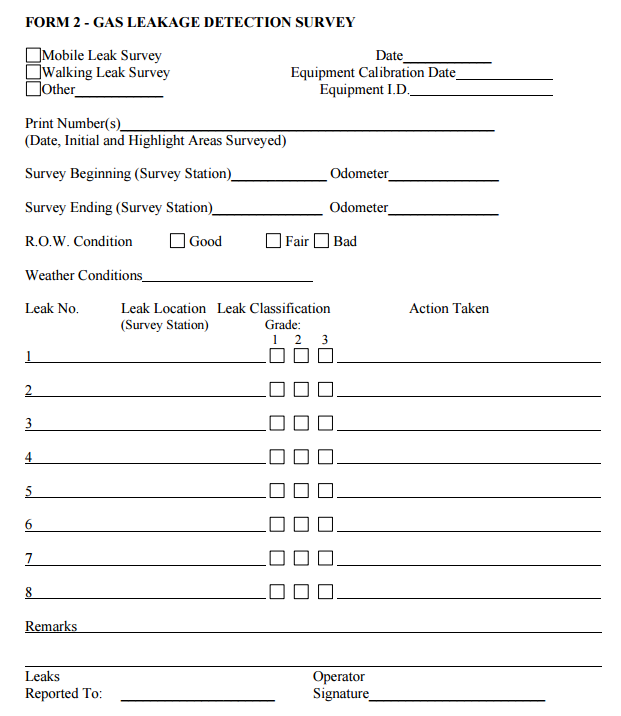

2. Gas Leakage Detection Survey Form (see section 10.0 below) must be completed by the Senior Leak Survey Technician to document the amount of mains and services surveyed and the number of leaks found.

3. A print of area surveyed shall be dated, signed, and highlighted by the Senior Leak Survey Technician to document the area surveyed.

Form 1 – Leak Report and Repair Order

Form 2 – Gas Leakage Detection Survey

Previews of the forms are shown below. Click the link above to open a PDF version for printing.

Form 1 – Leak Report and Repair Order (open PDF file)

Form 2 – Gas Leakage Detection Survey (open PDF file)

Heath Consultants Remote Methane Leak Detector [RMLD] - YouTube video