XYZ Utilities O&M Manual Rev. 2.0 - November 1, 2019

The links below take you to subsections within the current topic.

8.0 PERSONAL PROTECTIVE EQUIPMENT (PPE)

9.0 DOCUMENTATION/RECORDKEEPING

The purpose of this document is to provide detail on odorization monitoring and control within the Company gas distribution system.

This procedure includes:

a. Monitoring and response actions necessary to ensure that gas flowing within the Company gas distribution system is adequately odorized in accordance with regulatory requirements. The method of accomplishing this is as follows:

1. Providing the minimum requirements for odorizing natural gas

2. Monitoring odorant levels

3. Taking monthly tests to ensure the adequacy of odorization.

4. Responding to unacceptable odor detection thresholds

b. Procedures for operating & maintaining natural gas odorant-injection systems and odorant-monitoring equipment.

1. Monitoring odorization levels in the supply tanks.

2. Properly maintaining odor-sampling equipment.

3. Natural gas odorant-injection systems

4. Natural gas odorant-monitoring equipment

Text in maroon indicates a glossary term. Click the term to see the definition; click again to hide it.

Lower Explosive Limit (LEL) – The minimum concentration of gas or vapor in air below which propagation of a flame does not occur in the presence of an ignition source. Also known as the lower flammable limit (LFL).

Odor Fade – The loss of odor due to loss of odorant.

Readily Detectable Level (RDL) – Sometimes referred to as the Distinctive Odor Level or “DOL” is the gas-in-air mixture at which an observer with an average sense of smell can readily recognize an odor normally associated with natural gas.

Sniff test – A qualitative test without the use of an instrument, conducted by sniffing gas at an open valve.

Threshold Detection Level (TDL) or Threshold Odor Level - The gas-in-air mixture at which an observer with an average sense of smell can detect an odor change from ambient air.

The link below take you to the applicable federal regulation. The regulation will open in a new browser tab.

49 CFR 192.625

a. Measurement Department or designee shall be responsible for:

1) Operating & maintaining odorant-injection systems at gate stations, take stations, and at LNG facilities (except as noted below)

2) Ensuring adequate odorant inventories are available at injection points.

3) Performing odorant-level monitoring in accordance with applicable regulatory requirements or as otherwise requested.

4) Documenting, interpreting, and maintaining odorant level monitoring results and associated records.

5) Documenting, interpreting, and maintaining odorant-level monitoring results

6) Maintaining properly-calibrated odor-monitoring equipment

6.5 Preparation of Odorization Records & Surveys

6.7 Odorant Intensity Survey Records

Gas in transmission lines in a Class 3 or 4 location shall be odorized unless exempt from the regulations The odor may be produced from natural constituents present in the gas stream or by the injection of a chemical odorant at an appropriate point in the system.

All personnel working with odorization equipment will have a knowledge of the general operating principals involved. Personnel responsible for the operation, maintenance, and testing of odorization equipment will accumulate manufacturer’s service manuals and other reference material. These items shall be readily available for reference. The Measurement Supervisor is responsible for maintaining all equipment in satisfactory condition and establishing test and calibration schedules to properly maintain all odorization equipment to ensure that all gas is sufficiently odorized.

The odorization procedures and odorant used shall comply with the requirements of the State Regulatory Authority. Commercial odorants used by The Company will consist chiefly of tertiary butyl mercaptan. Acceptable odorants are mercaptan blends or equivalent.

Odorant shall be added to the gas at a rate such that the presence of odorized gas is readily detectable in concentrations of 20% of the lower explosive limit (LEL), or approximately 1% gas in air.

The amount of commercial odorant necessary to meet the above requirement is dependent on many factors including the type of odorant, the amount of sulfur present in the purchased gas, and the age and type of the system. Odorant injected at a rate between .30 and .50 pounds of odorant per million cubic feet of gas will generally be adequate.

Odorizers must be designed to control the amount of odorant supplied to the system without wide variations. Each odorizer shall be equipped with a device to permit determination of the amount of odorant injected. The State Regulatory Authority shall approve all equipment. Approved types of odorizers are positive injection commercial designs.

Odorizers and associated piping must be carefully designed and installed to avoid leakage. Threaded joints should be made with Teflon tape - ordinary pipe dope should never be used. Odorizer installations shall be designed with adequate storage to minimize refills, and to allow accurate checks of odorant usage.

Spilled odorant can be neutralized with liquid Clorox or commercial agents, which are available from the odorant supplier. Do not use dry bleach - it will explode in the presence of liquid odorant.

6.5 Preparation of Odorization Records and Surveys

A record shall be maintained of the odorant injection rate for each odorizer on the Company system, and for each individual check of odorant intensity made by the Company operating personnel. These records shall be prepared by the Measurement Technician and retained for a minimum of 3 years.

The Monthly Odorization Report form shall be prepared each month by the Measurement Technician from odorizer readings and meter readings available from the Measurement Department. Metered quantities will be used, when available, for entry on the report form and calculation of the odorization rate. Odorizer readings should be taken on a normal workday on or nearest to the first calendar day of the month.

6.7 Odorant Intensity Survey Records

The odorant intensity in each transmission system shall be frequently checked to assure that sufficient odorant is present in the gas stream. The only method acceptable for determining the adequacy of odorization is the use of an odor concentration meter, by a qualified Measurement Technician. These will give measurements of odorant intensity. Gas employees shall report any observed unusual odorant level, either weak or strong, to their supervisor.

The Measurement Supervisor shall establish a schedule for conducting odorant intensity checks at regular intervals at various locations on each separately odorized system.

Odorant intensity checks should be taken at the ends of each system to determine the area of weakest odorant intensity. These odorant intensity checks should be recorded on Odorant Check Log type form or in such manner that the Measurement Supervisor directs. The Measurement Technician should generally make the checks in conjunction with routine work.

24-hour checks of the odorant injection rate shall be made at the discretion of the Measurement Supervisor and reported on the Monthly Odorization Report form.

6.8 Incident Testing

Odor levels shall be immediately checked when an incident occurs involving natural gas. The odor level shall be checked in the vicinity of the incident utilizing an odor concentration meter.

Inadequate odorization can be detected through telemetry equipment, or through information obtained by personnel in the field which includes odor concentration meter tests or verbal notices by construction and maintenance personnel commenting on the intensity of odor in the gas. Customers and Service Personnel also provide input on inadequate or excessive odorization. In the event of odorization problems, an immediate response shall be made to determine and correct the cause.

Inadequate odorization in areas served by pump-type odorizers can be corrected by adjusting the injection rate.

Personnel operating an odorizer or monitoring odorization levels shall be either Operator Qualified or directed and observed, per the Operator Qualification Plan, when performing the following tasks:

The links below take you to locations in a different topic.

Covered Task(s):

Task #68 - Operating an Odorizer

Task #69 - Monitor Natural Gas Odorization Levels

Non-Covered Task(s):

Task #70 - Properties of Natural Gas and Abnormal Operating Conditions

Every employee that is required to conduct Odor Concentration Meter tests will be evaluated at the time the operator qualification test is performed, to confirm that they can discern certain olfactory items.

(1) The test will be conducted one-on-one by that employee’s immediate supervisor or designate.

(2) The test will be conducted by using either “The Pocket Smell Test” kit or “The Gas Company Smell Test” kit; randomly.

(3) Successful completion of the test will be documented using the appropriate form.

(4) Failure of said test may require further investigation of the employee’s olfactory system and does require that an alternate tester be selected and qualified.

8.0 PERSONAL PROTECTIVE EQUIPMENT (PPE)

Observe all personnel and procedural safety procedures as necessary per job requirements.

CAUTION: Mercaptan mixtures are generally flammable and toxic in concentrate form. In addition, a spill of mercaptan could cause numerous odor or leak complaints. As a result, personnel handling mercaptan mixtures shall be trained and qualified in odorant injection techniques and shall wear the appropriate level of PPE.

9.0 DOCUMENTATION/RECORDKEEPING

a. Odor level testing results, record of active monitoring locations, other records including location and type of odorant-injection equipment, odorant used, and ratios of odorant injected shall be retained regionally in a manner applicable to each system for the life of the facility. and shall be made available for inspection, if required. Example records are shown in the listed attachments.

b. All forms and data sheets associated with the implementation of this instruction shall be stored with the applicable job file or electronic data base for as long as the pipeline remains in service.

1. Odor level testing results, records and documentation shall be retained for a minimum of three (3) years.

2. Personnel training and odor-monitoring test equipment calibration and repair records shall be retained regionally for a minimum of three (3) years.

The link below opens a reference document in a new browser tab.

Odorator Manual Rev. J (PDF format)

Odorator Manual courtesy of Heath Consultants

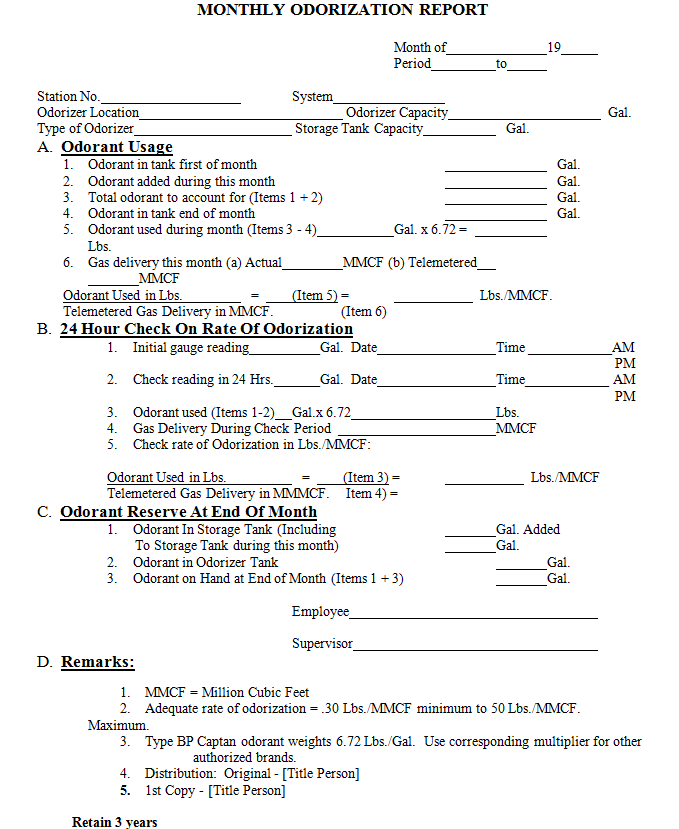

Attachment 1 - Monthly Odorization Report

Attachment 2 - Odorant Check Log

Attachment 1 - Monthly Odorization Report (open PDF file)

A preview of the form is shown below. Click the link above to open a PDF version for printing.

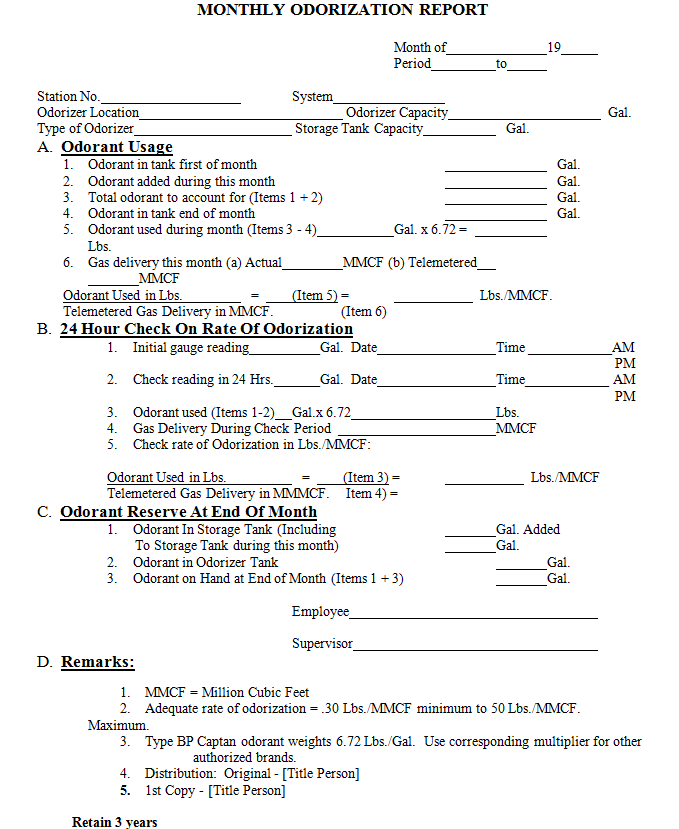

Attachment 2 - Odorant Check Log (open Word document) (open Excel document)

A preview of the form is shown below. Click the link above to download a Word document or Excel spreadsheet for editing. You must have the appropriate application installed on your system or device to open these files.

ODORANT CHECK LOG |

|||||||||

TEST |

TOWN |

DATE |

(CHECK ONE) |

(CHECK ONE) |

EMPLOYEE |

||||

TYPE OF TEST MAKING |

|||||||||

NOSE |

ODORTESTER |

TITRATOR |

WEAK |

OK |

EXCESSIVE |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Retain 3 years